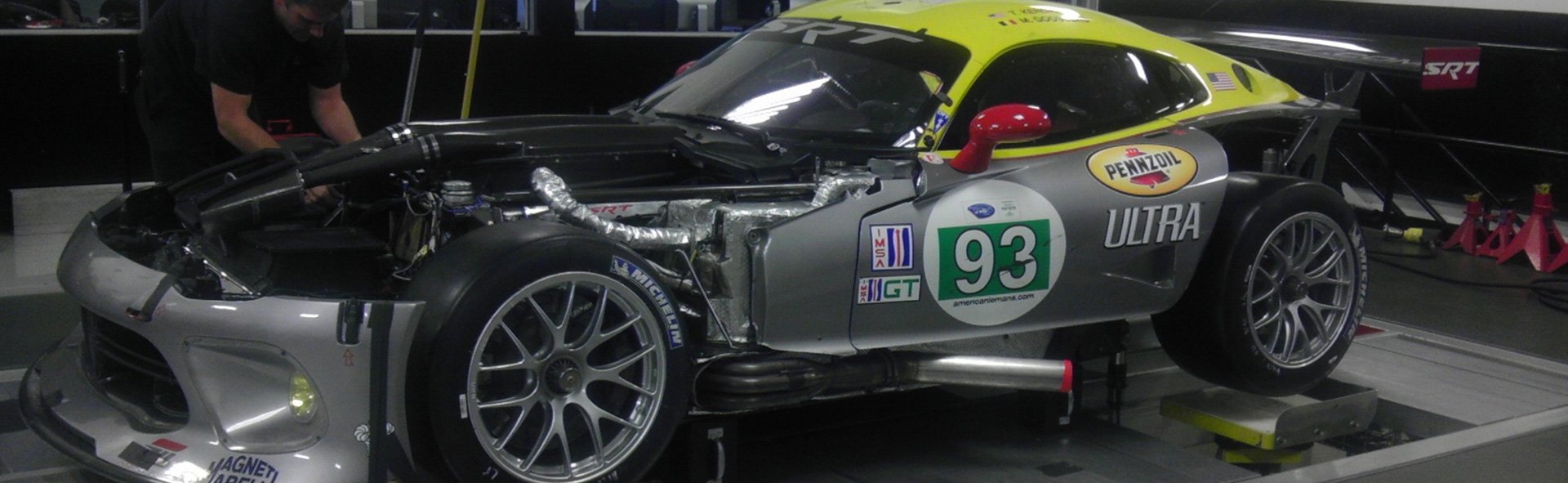

Testing and test development for any kind of dynamic system.

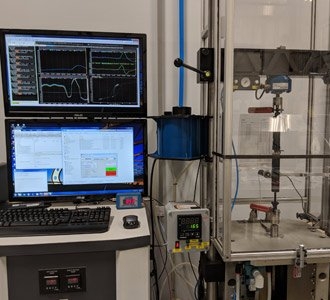

Kaz Technologies is a data-driven company. In fact, to get the objective data we need to provide meaningful solutions, we’re obsessed with dyno testing development and data acquisition.

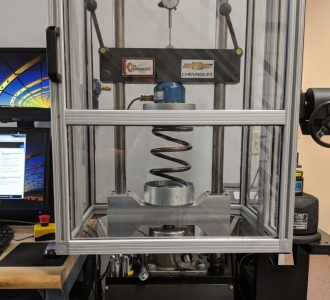

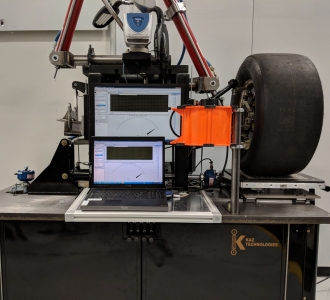

That’s one reason we have every kind of testing machine imaginable. We have hydraulics machines, electro-magnetic machines, ball-screw actuator machines, and electric motor machines.

Whatever the driving mechanism is, we have the ability to adapt it across the board to achieve the tests we need from the standpoint of accuracy, max load, acceleration capabilities, frequency, and durability. If you have any questions please contact us today through our Testing and Analysis webform!